News

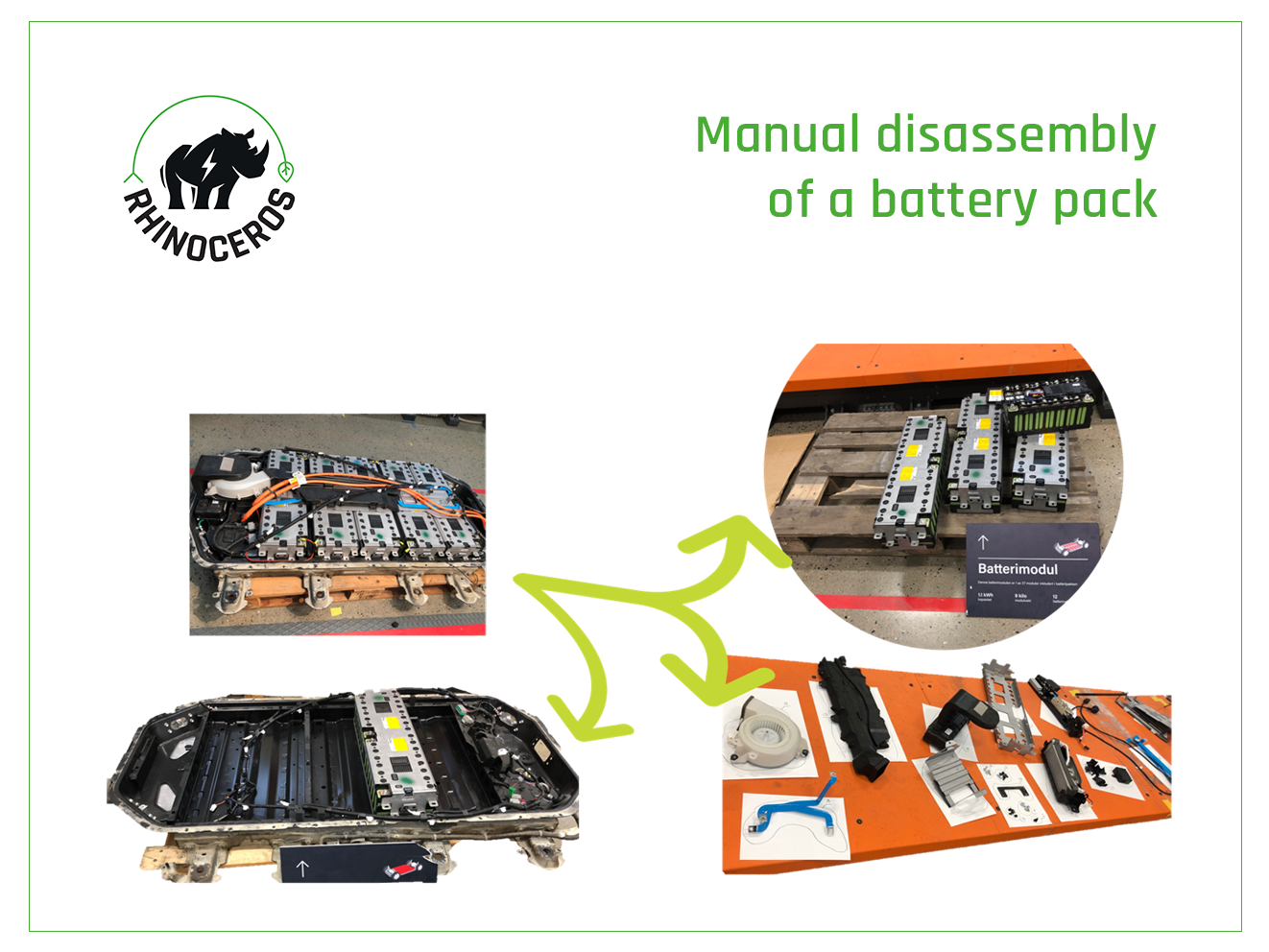

Manual dismantling of a battery pack

16/03/2023

During the first six months, University of Adger [UiA] received three battery packs (out of the five planned) and manually disassembled them, opening for further analysis. In the future, this activity will feed a digital repository as promised in the first delivery of Work package 3.

For each battery pack, the analysis includes:

- a precedence graph informing how components are connected, which, in the upcoming steps, will help determine the best order to dismantle these components automatically.

- an Excel table listing the characteristics of each type of component other than geometrical characteristics: number of items, mass, material, or other specific features.

- 3D scanning in the form of point clouds (pcls) to provide information on the geometry and texture of the components constituting the different battery packs. After testing several hardware and algorithms, two of them have been selected.

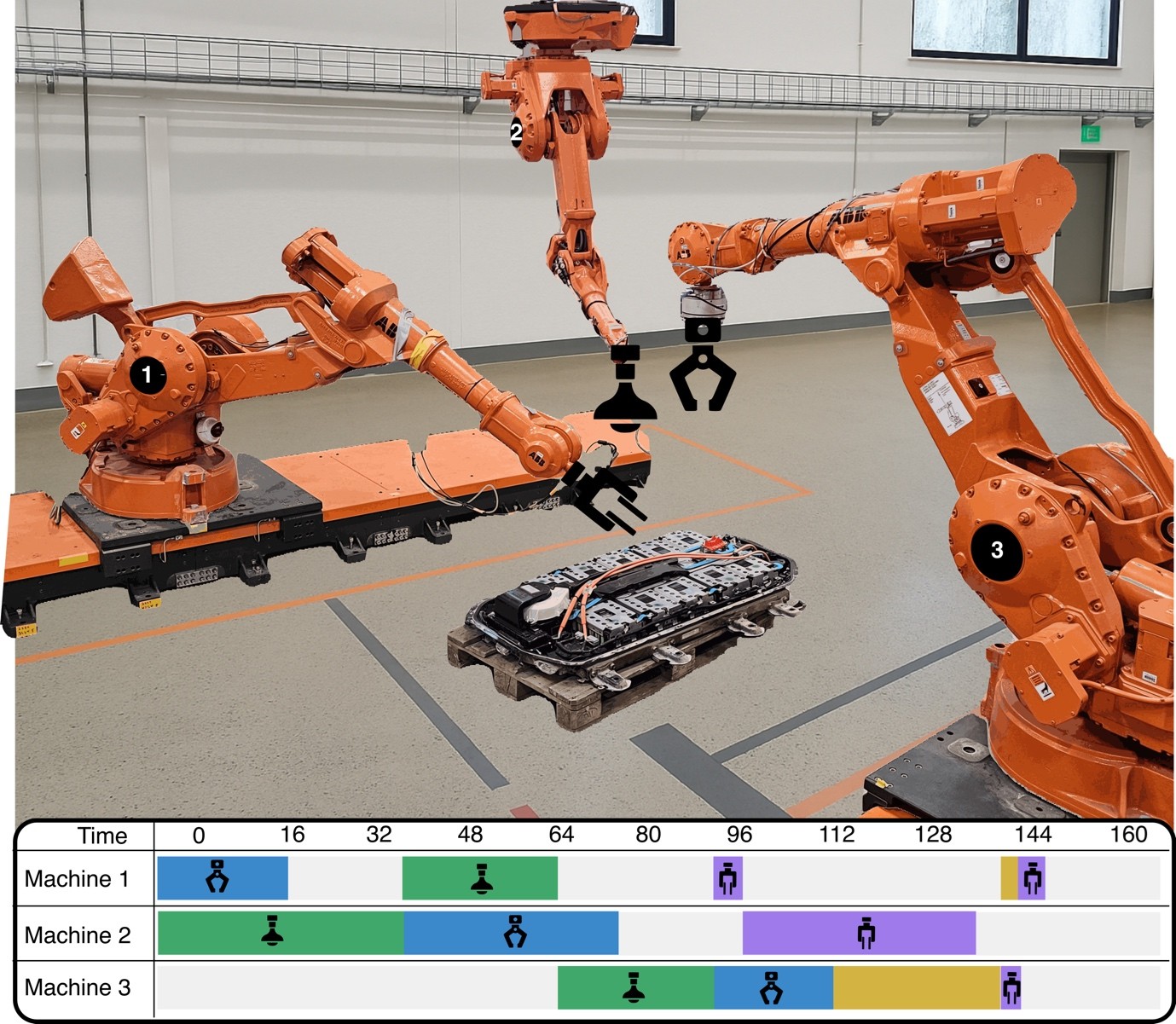

In parallel, several of the main important tools have already been identified based on the manual disassembly of these three battery packs, and a tool changer is under development. End effectors (tools) will be able to be changed quickly, including their connection to their power source (electric and/or pneumatic) and their signals.

In addition, the disconnection of power and signal cables using non-destructive methods – operation identified as critical, has been investigated and currently, a concept is prototyped and evaluated. The main challenge is to design a tool that “fits them all”. Additional activities carried out within WP3 have investigated different sorting (characterisation) methods, based on temperature, mass loss, and other flaws, such as deformations, leakage, trace of heat damages.

Safety has also been an important part of the work completed within WP3 during the first six months. A complete monitoring system and a set of safety measures to be followed during the scheduled demanufacturing (discharge, sorting and disassembly) activities have been established.

During February, when the researchers started examining the available methods for automatic task planning using search algorithms and/or reinforcement learning, the robotic system adaptability was discussed. In anticipation of the implementation and testing phases of these adaptive robotic methods, thorough battery knowledge stored within the digital repository must first be developed.

News